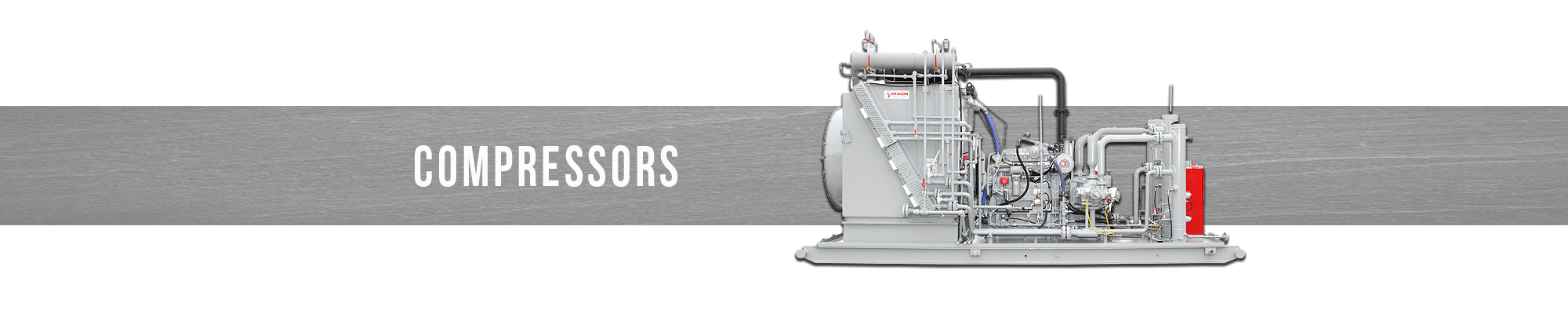

Gas Compressors

HALF ROUND DUMP BODY

Dragon compressors are built to keep your gas lift operations running 24/7. Our units are severe-duty engineered and manufactured in-house to be exceptionally durable and reliable. Each unit features the best components, including Caterpillar or Cummins engines and Ariel 3-stage compressors. They meet the highest standards in the industry, they’re competitively priced, and they’re ready to ship.

Units Available:

95HP – 400,000 cf/d

145HP – 975,000 cf/d

200HP – 1.2 million cf/d

380HP – 2 million cf/d

SPECIFICATIONS

• Driver: Murphy eics-engine integrated control system, integrated cd ignition, air/fuel control and electronic governing speed control.

• Exhaust: Critical grade exhaust silencer with 30 to 38 dba noise reduction and murphy emissions kit with precious metals catalyst.

type k thermocouples to monitor catalyst inlet and outlet temperaures and two exhaust outlet test ports.

• Start System: 24V DC electrical (air/gas start optional).

• Control Panel: Murphy/enovation TTD2-T annunciator housed in weatherproof, removable rear door and hinged front door with viewing glass

window. Suitable for class 1, div. 2, groups C, & D hazardous areas. Modbus RTU (slave) rs232/485 communication.

• Unit Inlet Suction Strainer: Inlet to first stage scrubber includes removable spool piece with suction strainer to protect unit from dirt and

slag from pipeline.

Options

• Condensate Drains: Conndensate line is route from dump valve through heated scrubber skirt to help keep condensate from freezing up due to flashing.